| Other known Employees: |

Please

click here for a more complete list of known employees of American Viscose.

Baker, Frank - 2

"My great-grandfather worked for American Viscose

as a trucker at the time of his death. His name was Frank Baker. He was also a volunteer

fireman although I'm not sure where. I have heard that it was near Viscose. He died at the

firehouse August 21, 1940. His home address at the time was 405 Reaney St., Chester."

Bennington, Lee - 3

"I went to work for American Viscose in September of 1948. I

worked in the Viscose Dept, on "C" shift. The shift foreman was

Roger Culver. The department superintendent was "Viscose" Smith.

Sorry, I don't believe I ever heard his first name! There were over 3000

employees back then."

Bettner, Ed - 3

According to the September

7, 1951 Chester Times feature article below, started with the Hook plant when it opened

and still was associated there at that time.

Casperson, Samuel - 3

According to the September

7, 1951 Chester Times feature article below, started with the Hook plant when it opened

and still was associated there at that time.

Copson, Ernest D. - 3

From Claymont

According to the September 7, 1951 Chester Times feature article below, started with the Hook plant when it opened

and still was associated there at that time.

Derrick, Ross - 7

Pictured

with the Glee Club in 1918

Dotson, -?- - 5

Elliott, Jacy - 3

According to the September 7,

1951 Chester Times feature article below, started with the Hook plant when it opened

and still was associated there at that time.

Hill, William - 5

Minnich, John A. - 5

"My father, now 90, John

A. Minnich was recruited by two men who came to see him in 1939 in

Northampton, PA. Dad had worked in R&D for several silk mills in the

area. The men said if dad would take a job in Marcus Hook PA, he would be

working in the R&D building. Dad also told them about his friend

Dotson (can't remember the first name) and both moved the "long"

distance with their families to the model village where we lived a short

while until dad and mom bought a house on White Avenue in Linwood. Crown

Rayon sent him to Philadelphia Textile Institute where upon completion, I

remember him coloring in little squares on what appeared 8 1/2 x 11"

paper so the finished colored papers could be given to loom operators.

I am trying to find for a

friend in Alaska any information on an employee named William Hill. His

son does not have any pictures of his father who died a long time ago.

Anyone with such a picture would be appreciated."

Mortimer, Michael J. - 3

According to the September 7,

1951 Chester Times feature article below, started with the Hook plant when it opened

and still was associated there at that time.

Murphy, Frank J. - 1

Nickson, Elizabeth "Bett"

- 4

Nickson, Ellen - 4

Nickson, Ethel (1912 - ?) - 4

Nickson, Harry (c. 1915 - 1917) -

4

Nickson, Mary "Mame" - 4

Nickson, Pat - 4

Nickson, Theresa (August 1917 -

December 1926)- 4

"My grandmother and all of her sisters

worked at Viscose. They were known as the Nickson sisters. Each began working there at

the age of 14 and they all worked together on the 2nd floor. My grandmother, Theresa

Nickson, worked at Viscose from August 1917 until she married in December 1926. The

other sisters names were Ethel (the eldest, started around 1912), Mary (2nd oldest, went

by Mame), Elizabeth (went by Bett), Pat, and Ellen. They also had a brother, Harry, who

worked at Viscose for 1 or 2 years around 1915."

Oaks, Harold J. - 3

From Ridley Park

According to the September 7, 1951 Chester Times feature article below, started with the Hook plant when it opened

and still was associated there at that time.

Rivers, Hal - 6

Viscose of Marcus Hook owned and operated "Kennett Square Machinists" in Kennett Square Pa. I know because I worked there as a "Gear Cutter" in 1951. They produced the gears and machine parts for Viscoe. The tool room was an integral part of the shop . Charles Dannanker from East Roland Road, Parkside was manager of the "tool room" and gear cutter equipment.

After I was discharged from the Army following Korea I was employed at

Viscose which was now the "FMC" corp. engaged in the manufacture of "Film" products. I was a caustic mix operator on the night shift.

Scott, Joseph H. - 3

According to the September

7, 1951 Chester Times feature article below, started with the Hook plant when it opened

and still was associated there at that time.

|

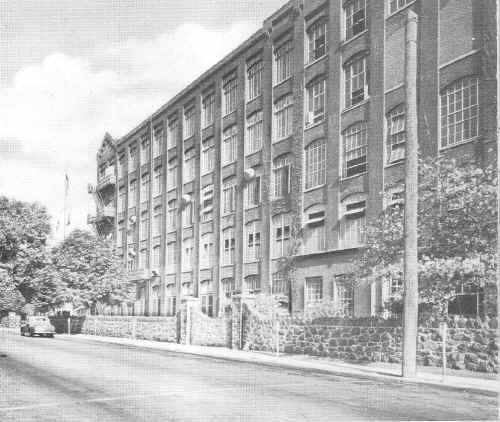

| Company History: |

(Thanks

to Lee Bennington for sharing the following history from a September 7, 1951 Chester Times feature article):

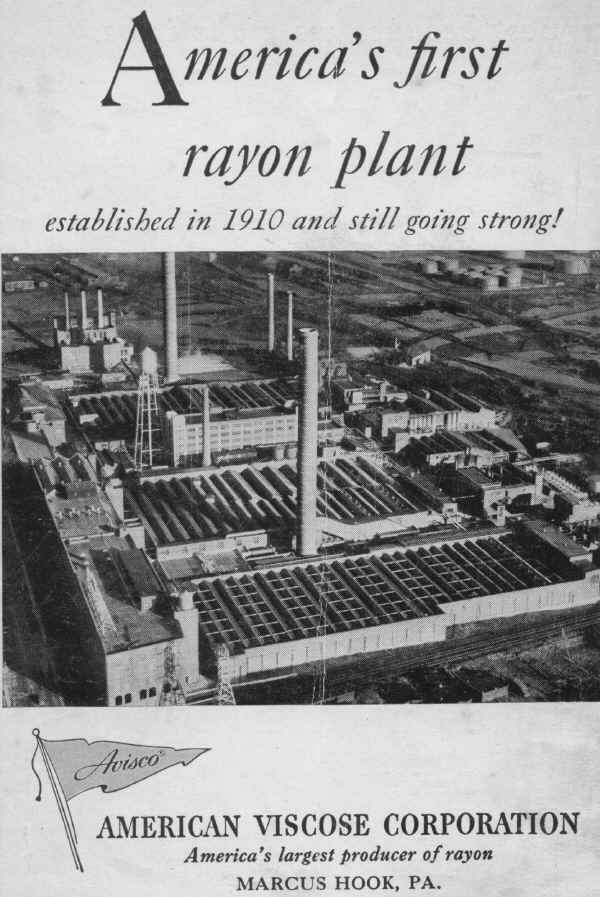

American Rayon Industry Born at Marcus Hook

Samuel Agar Salvage, the founder of the American rayon industry, was born in London in 1876, the same year the

Chester Times was started. That was also the year that Alexander Graham Bell invented the telephone and Louis Pastuer developed the theory of germs. There were, of course, no radios, no automobiles, no airplanes, and the man-made fiber called rayon was yet to be produced.

Seventeen years later young Samuel Salvage sailed for the United States to seek his fortune—one of 400,000 men and women who immigrated to this country in 1893. Another 17 years passed before Salvage came to Marcus Hook.

Here, at his suggestion, the English textile firm of Samuel Courtald & Co. built the first commercially successful rayon plant in this country. Spinning “artificial silk”, as it was called then, started at Marcus Hook on a Sunday night, just seven days before Christmas in 1910.

Production Then and Now

Total United States production in 1911, the first full year, was 362,000 pounds of yarn. All of it was made at the Marcus Hook plant of what is now the American Viscose Corp.

Forty years later, in 1950, total United States production was 1,260,000,000 pounds. In 1950 American Viscose Corp. alone in its seven rayon plants made 416,000,000 pounds, or more than 1000 times as much as it turned out in 1911. Production this year (1951), both by the industry as a whole and by Avisco, is expected to be even greater.

The growth of rayon to its present outstanding place among the world’s outstanding textile fibers is one of the phenomena of this industrial age. Its success in this country is credited largely to the perseverance and confidence displayed by Samuel Salvage.

After landing in New York in 1893, young Salvage went first to Cincinnati, OH, where he worked for a company of wholesale china and glass merchants for a year. According to his own story, he “broke too much glassware” and left in 1896 to go to New York.

Hired by Linen Firm

Business conditions were poor that year and young Salvage rang many a door bell before he was hired by J. B. Locke & Potts, a linen firm. He worked there several months, then became associated with William M. Crowe, a yarn merchant, and--in 1897—started his own small business as an importer and salesman of cotton yarns. Under the name of S. A. Salvage Co., he gradually built up an excellent trade, particularly for fine-count English yarns.

Among the goods he imported was some “artificial silk” from Germany. He found a market for it in the braid and trimming trade, but no one else wanted it. Deliveries from Germany were poor, Salvage recalled years later, “but I believed in the product,” he said. “When Samuel Courtald & Co. started to make artificial silk, I got hold of some and sampled the trade with it. It was entirely satisfactory, and I got their agency here in 1908”.

It was the next year that Salvage wrote Courtalds to suggest that they buy the viscose patents for the United States and build a plant here. The proposition, said to have been sent on a postcard, was accepted, the American Viscose Co. was formed, and Marcus Hook was chosen as the site for the plant.

Building was soon started, but was not completed, when on that fateful Sunday night, just seven days before Christmas in 1910, a little group of Englishman and Americans gathered anxiously to watch the first yarn form as the viscose solution was pumped through a spinning jet. As the yarn formed the Americans grew excited, but the Englishmen, true to their tradition, did not change expression. After all, they had seen the same thing at Courtalds in Coventry, England.

The next morning at seven o’clock, without ceremony, the first five machines were started. Soon rayon was all over the floor, stuck to the walls, the benches and the ceiling, for only a few men who had come over from England knew how to handle the sticky, wet yarn. Most, if not all, the rayon made on that Monday and for some time to come, went into the waste basket.

In 1916, Salvage went to London to tell the directors that a second plant was needed to satisfy the growing demand for yarn. With some trepidation he reported that eight million dollars were required. “They told me,” he said in later years, “to go right ahead—what was I waiting for? They were—and are—very far-sighted people, and have encouraged and stimulated me to an extraordinary degree. The confidence they placed in me has been priceless.” They further demonstrated their confidence in him that year by electing him vice–president of Viscose Co.

The second plant was built at Roanoke, VA, and started operating in October 1917. It was followed, as the years went on, by plants at Lewistown, PA; Parkersburg, WV; and Front Royal, VA.

Name “Rayon” is Adopted

As other producers entered the field pioneered by the Viscose Co., the need was felt for a name of its own for the fiber known as “artificial silk”. Salvage presided at a conference in 1924 to choose a name. Many were suggested, among them “glos”, “filatex”, “klis” (silk spelled backwards), “glistra” and “filacel”. Kenneth Lord of the textile firm of Galey & Lord, Inc., suggested “rayon”. The name met with wide approval and the new fiber at last achieved its own identity. Samuel Salvage, who had always advocated that the man-made fiber should stand on its own merits, was well pleased.

In May 1925, Salvage was elected president of the Viscose Co., a post he held until 1937, when he became chairman of the board. Two years later he retired as chairman, but remained as a director and consultant until his death in 1946. During his active tenure, the company was the leading producer of rayon in the United States, a position it still firmly maintains.

Growth Credited to Research

Born in the laboratory, rayon owes its success, it is generally agreed, to continuing research. It is a search for new and better products, at lower prices, which together make for a better life for everyone.

The fact that rayon is man-made means that, like the automobile and the airplane, it can be engineered to meet the requirements of an intended use. For this reason, American Viscose Corp. has long recognized that the rayon industry requires an extensive and well planned research program covering all phases of the business from raw materials to the production of finished products by its customers.

This research program is centered largely at Marcus Hook. Here, 12 years ago, American Viscose Corp. established its unique textile research department, which contains the elements of six or more full size textile mills. There is one for cotton spinning, one for the woolen system of spinning, one for the worsted system, one for warping and weaving, one for knitting, and one for dyeing and finishing. Here, under one roof, may be seen and studied methods used throughout the textile industry in that infinitely complex process by which textile fibers are converted into finished goods.

The department’s work is primarily research on new developments—new techniques, new machinery, new fabrics, new fibers for new uses, and new uses for existing fibers. At the same time, it constantly checks the company’s products to make sure they perform as its customers wants them to.

At Marcus Hook also are the company’s chemical research and mechanical development departments. At Nitro, WV, is a rayon staple development plant, in addition to the commercial rayon plant there, and, in New York, is the fabric development department.

Rayon Suits and Carpets

New kinds of rayon, new products of rayon and new markets for rayon are continually being developed. In 1950, for the first time rayon was used in more than half of all men’s summer suits and in heavier weight suits it passed from the experimental stage to volume production. This fall and winter the stores will feature all-rayon and rayon blend suits and topcoats in a wide range of colors and tailoring.

Avisco “15”, a new carpet staple, was introduced only a year ago. Yet seven out of ten of the carpet lines on sale today contain rayon.

Rayon is playing a much bigger part in the current mobilization for defense than it did in 1940 and 1941, and it played a big part then. So far, the bulk of the rayon covered by defense orders is going into tires, linings for uniforms, aerial delivery, and cargo parachutes. The armed services, however, are evidencing greater and greater interest in rayon for use in uniforms.

Thus the company which Samuel Salvage founded 41 years ago continues to expand. Built originally by the English firm of Courtalds Ltd., the corporation is now largely owned and managed by Americans. There are 16,000 shareholders, many of whom are among the corporation’s 22,000 employee’s.

The corporation is managed by a board of directors elected by those shareholders. Seven corporation executives are members of the board. Chairman of the board and president is Dr. Frank Reichel, who joined the company in 1946, when it acquired the assets and business of Sylvania Industrial Corp., now the Sylvania Division, which makes cellophane.

Marcus Hook Plant Managers

Harry Johnson Grant was plant manager until 1911 and Dr. Charles A. Ernst took over and served in the post until 1916 when Charles E. Baldwin became manager.

Baldwin was followed by J. Arthur Hayes in 1925 and he was in the post until 1939 when Fredrick F. Long became plant manager. Long was transferred to the firm’s Lewistown plant in 1949 and was succeeded by Harold J. Michel, the present plant manager.

Seven local workers who started with the Hook plant when it opened still are associated there. In this group are Samuel Casperson, Ed Bettner, Joseph H. Scott, Michael J. Mortimor, Harold J. Oaks of Ridley Park, Ernest D. Copson of Claymont and Jacy Elliott.

|